Blister packaging is one of the most effective ways to showcase and protect your products. You’ve seen it everywhere; a clear, durable plastic cover holding items like tools, batteries, or cosmetics against a bold printed card. It’s clean, professional, and instantly recognizable.

This type of packaging doesn’t just protect your product, it sells it. The crystal-clear display lets customers see exactly what they’re getting, while the custom backing card gives you the perfect space to tell your brand’s story, highlight features, and make a lasting impression.

When presentation matters, blister packaging makes your product stand out on the shelf and in the customer’s hands.

See How we WORK in Blister Packaging

Blister Packaging Manufactures

The Original & Affordable

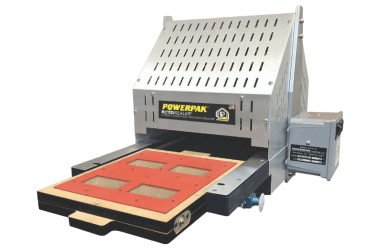

2-in-1 Blister/Clamshell Packaging Machine

- 4 - Station (Manual Rotary Table)

- Self - Indexing Guide

- Accommodates Blister Packs & Clamshell Packs

- 1-3 Person Operation

- Virtually Maintenance Free

- Runs Quietly & Economically

Affordable Retail Packaging

Whether you’re looking for blisters, cards, or clamshells, POWERPAK has got you covered!

- Clear visibility for product display

- Tamper-proof seals for added security

- Customizable shapes and sizes

- High-quality, durable materials

POWERPAK’s Blister packs and Blister Cards are made with only the highest quality materials. All cards and blisters are 100% consumer recyclable.

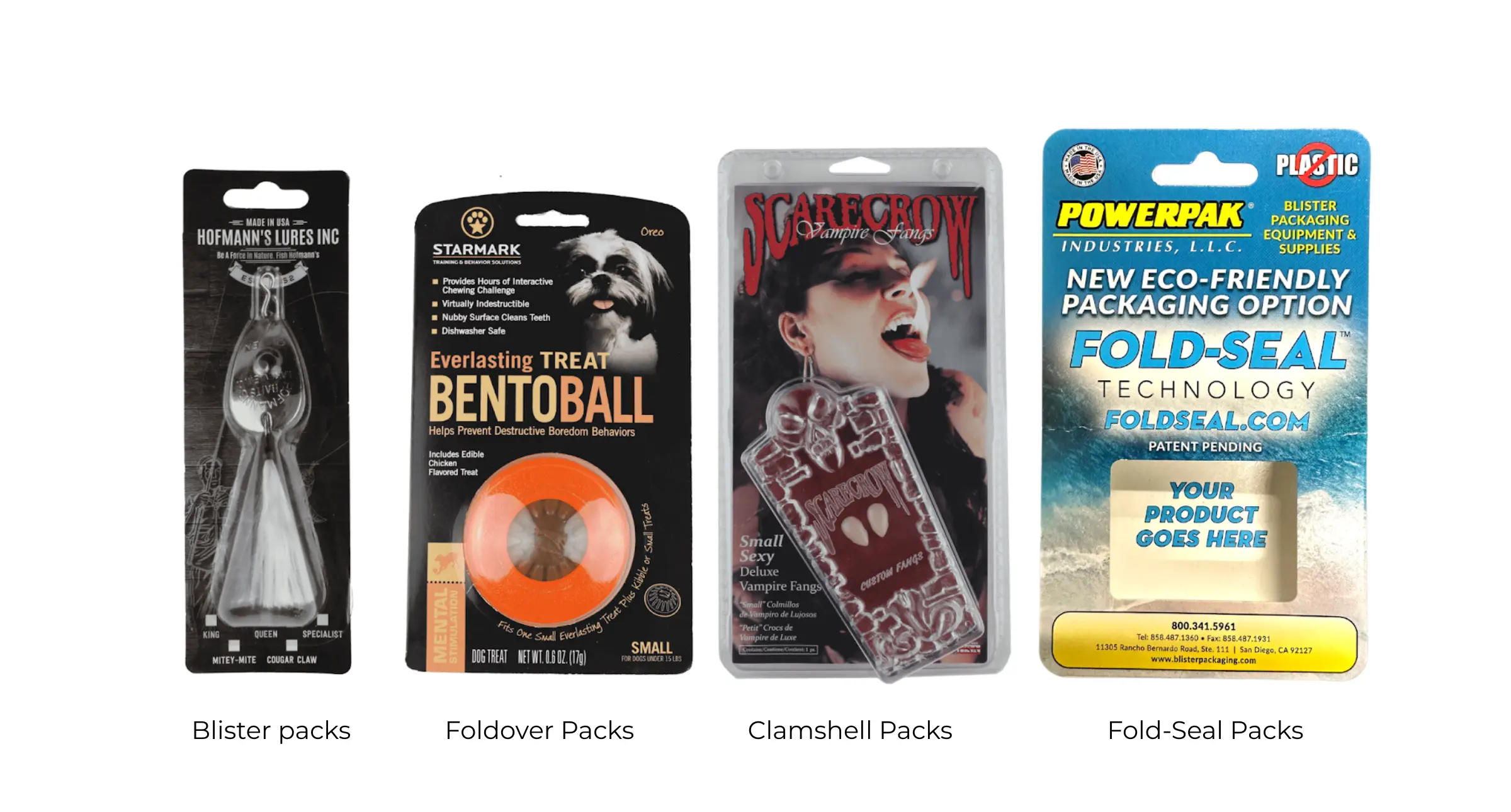

Blister packs use a clear plastic cavity sealed to a paperboard or aluminum backing to securely hold products. They offer excellent visibility, tamper resistance, and protection from dust and moisture, making them ideal for pharmaceuticals and retail goods.

Foldover packs feature a plastic blister folded over itself and sealed on all sides. This creates a strong, fully enclosed package that provides higher security and is commonly used for tools, electronics, and hardware products.

Clamshell packs consist of two hinged plastic halves that snap or heat-seal together. They are durable, theft-resistant, and widely used in retail for electronics, accessories, and consumer products.

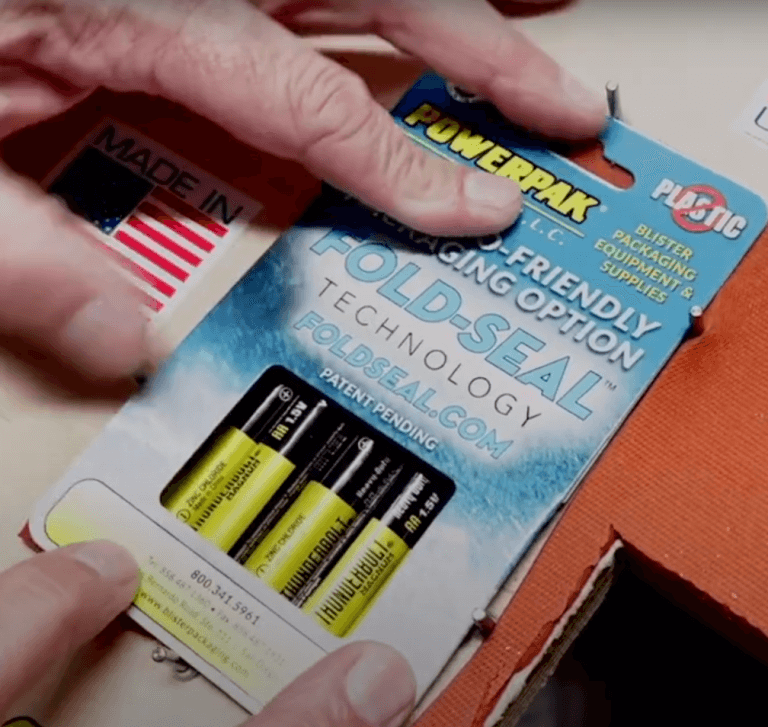

Fold-seal packs are made by folding a plastic sheet around the product and heat-sealing the edges. They are cost-effective, lightweight, and ideal for small, lightweight retail items.

Blister-carded packaging is popular across many markets and product categories, such as:

Club stores and major retail chains

Home improvement, hardware, and tools

Hunting, fishing, and outdoor gear

Sports and recreation items

Health, beauty, and cosmetics

Household products

Electronics and gadgets

Office and craft supplies

Toys and games

Automotive parts and accessories

Other PRODUCTS THAT WE PROVIDE

Blister Packaging Machinery By POWERPAK

The Original 4 Station Blister Clamshell Sealer

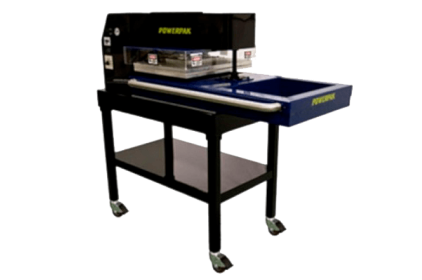

The Original Flip Sealer Blister Packaging Machine

The Original 4 Station Blister Clamshell Sealer Clean Room Model

2 Station Blister Clamshell Sealer Club Pack Model

Blister Packs

Clamshell Packaging

Foldover Packs

Fold-Seal™ Packaging

Folding Cartons

Step 1: Project Begins

The process starts with a meeting with the customer (email, call, video, or in person) and understanding about the requirements..

- The product and its use are discussed.

- The customer shares a sample or drawing

- Packaging goals, materials, and timeline.

- Card size, shelf space, and product highlights are reviewed.

- Hang-hole style and budget are discussed.

- An estimated price and delivery time are shared.

Step 2: Design

- A CAD design & card graphics are created based on the discussion.

- The customer reviews the designs and gives feedback.

- Changes are made until the final design is approved.

- Other packaging needs (boxes, pallets, etc.) are also finalized.

Step 3: Prototyping

- The customer places an order for prototypes.

- A sample mold is made, and a blister sample is produced.

- Samples are tested for fit and function.

- Samples are sent to the customer for approval.

- Minor changes (first revision) are usually free.

Step 4: Tool Development

- The customer approves the sample and places an order for production.

- Tooling and production parts take about 3 – 4 weeks.

Step 5: Production & Delivery

- Production is scheduled immediately after approval and receiving purchase order.

- Blisters & Cards are then produced and shipped to the customer.

Step 6: Repeat Orders

- Repeat orders usually take 3 to 4 weeks to ship.

- Customer service handles orders, prices, and support.

- The sales team handles new opportunities and technical questions.

- For large-volume orders, an inventory program can reduce delivery time.

Step 7: Lead Times

- Concept drawing: 3 to 5 days

- Prototype samples: 5 to 7 days after concept approval.

- Changes to prototypes: 2 to 7 days.

- Final production samples: 2 to 4 weeks.

- Full production: starts immediately after receiving the purchase order.

Need more details? Contact us and we’ll answer all your queries personally.

WHY BRANDS LOVE US

Powerpak Industries is an exceptional company that I have had the pleasure of working with. Their dedication to providing the best blister packaging solutions is truly remarkable and has made them a top choice in the industry. I have had the pleasure of working closely with Bob and Melody, the dynamic duo behind Powerpak Industries, and I can confidently say that their passion for their work is unmatched. They are always willing to go above and beyond to ensure that their clients receive the best service possible. From the initial design stage to the final product, Bob and Melody are involved in every step of the packaging process, ensuring that every detail meets their high standards. Their attention to detail and commitment to quality is evident in the final blister packaging product, which is always top-notch. Working with Powerpak Industries has been a true pleasure, as their team is not only knowledgeable and professional but also friendly and approachable. They truly listen to their clients’ needs and work tirelessly to provide the best solutions for their packaging needs. It is no surprise that they have a loyal customer base, as they consistently deliver exceptional results. I highly recommend Powerpak for anyone looking for the best blister pack machine solutions and an outstanding customer experience. Bob and Melody’s dedication to their work and their clients is truly admirable, and I am grateful to have had the opportunity to work with such an amazing blister packaging company.

I have been working with Powerpak for ~5 years for our blister machine packaging needs. They have been very helpful selecting the right blister pack machine products for our business needs and have always been available if we had questions or needed help with our blister machine equipment. During a recent move from CA to NV, they also recalibrated our equipment and crated it for safe transport. Most recently we started a conversion from blister to enviro-friendly plastic free blister packaging which required several design iterations to capture the essence of a secure product in enviro-friendly packaging, but Powerpak was patient with our changes and went full throttle when it was time to print. As a small business, we love supporting other small businesses and are grateful to have Powerpak as our packaging partner.

Finding the Powerpak Blister Machine for our small business was the best thing that could’ve ever happened to our brand. We were able to accept an order for over 100,000 units and save over $20,000 by not having to pay a contract manufacturer to manage the job for us. This machine alone has significantly improved our blister packing machine capabilities and allows us to continue to grow our business due to the speed in which it completes our blister packaging machine. Not to mention, the customer service that Bob and Melody provide is unmatched. We are grateful for our relationship with Powerpak.

Throughout our 13-year partnership, Powerpak has exhibited exceptional service and dedication to our company. The quality of the products/services provided has been exemplary, consistently meeting and often surpassing our expectations. Powerpak has always accommodated and valued our business needs, and more importantly our relationship. Powerpak’s promptness in addressing our requirements, coupled with their reliability in meeting delivery deadlines, has greatly contributed to our operational efficiency. Thank you once again for your outstanding blister packaging service and collaboration to our company’s success. We value our partnership and look forward to continued growth together.

I have been working with Powerpak since the week I went into business 27 years ago. Someone recommended them to me and I have been a customer ever since. I cannot say enough about their integrity and how I was treated right from the beginning. They make the best blister machine packaging and take care of their customers 100%. Look no further if you are looking for a terrific team to work with.

I have been doing business with PowerPak Industries for about two years, and I have consistently received outstanding blister packaging customer service. Despite the small size of my company, which initially provided limited business for them, the PowerPak team exceeded expectations in accommodating my needs. I am extremely pleased with our business relationship and eagerly anticipate many more years of successful business growth, with complete confidence in our packaging!

We have been working with Powerpak for quite a few years now and they have been nothing short of amazing! Their blister packaging machinery products have always been high quality and the customer service is exceptional. Highly recommend.

Cherub Marketing has been using PowerPak for over 25 years. We sell products to the U.S. military—it has to be perfect every time.Thank you, PowerPak, and thank you to the PowerPak team.

You’re the best.Cherub marketing,inc. 10436 artesian springs ct

Our Story

When it comes to blister packaging, we may know a thing or two.

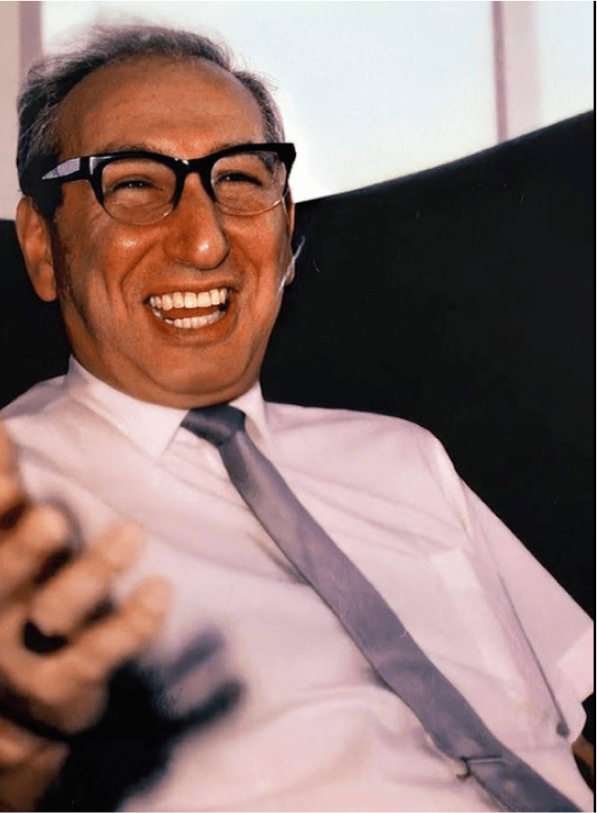

Thanks to the late Peter Green. Proud dad of now CEO, Bob Green.

He not only left behind a charming smile, a witty sense of humor, and a loving family… but something important Powerpak incorporates into our business practices today: INTEGRITY.

It all started when Peter Green owned a company “Century Printing LTD.” He was approached by Aaron Fish, CEO of “ILCO UNICAN” who had a hardware line. He complained that their products were being stolen out of bins. Peter took some samples and saw his good friend and thermoforner, John Fisher. John mostly formed chocolate trays, but Peter asked him to try to form clear plastic over ILCO Unican’s products.

After successfully doing so, he printed the cards, created the machine, sealed the packs and the rest remains history!

FAQS.

What is retail blister packaging?

I have a product, how do I start?

How do I send my artwork?

Where are you located?

Why offer a lifetime warranty?

Why put my trust in Powerpak?

Blister packaging, is a durable and customizable solution featuring a clear plastic cavity sealed to a backing, ideal for protecting and displaying products like retail goods, electronics, and cosmetics.

Blister packaging comes in several forms, including:

- Front face Seal Blisters: Clear plastic sealed to a flat backing.

- Full Blister Cards: Fully encloses the product with a durable seal.

- Clamshells: Hinged designs that open and close.

- Pharmaceutical Blisters: Individual compartments for pills or tablets.

These forms can be customized to fit specific product needs.

If you have a new product you believe is ideal for retail, we are here to assist you. Contact our team, and one of our experts will provide dedicated guidance and resources to help you take the next steps. We may request product samples to be sent to our main location, enabling us to create a mockup design to ensure we’re aligned with your vision. Additionally, we’ll collaborate with you to determine the most suitable packaging options, tailored to your product, budget, and volume requirements.

We work in CMYK format and our preferred format for artwork is Adobe Illustrator (Ai). Within the art files, all fonts should be converted to outlines and any linked images should be imbedded. Text and graphics should be at least .125″ away from any cut and or trim areas, to allow for cut tolerance. The file should have a .125″ bleed beyond the die line. Corners of the card should have a radius (recommended .25″) because square corners tend to dog ear. The hang hole should be placed at balance point. You will always receive a hard copy proof via mail to review and approve before production.

The Headquarters for Powerpak Industries LLC. is located in San Diego, California. They are a proud USA based company who serves companies all over the world.

Why do you offer a lifetime warranty on your equipment?

We offer a lifetime warranty on our equipment because we are confident in the quality, durability, and craftsmanship of our products. Our goal is to provide our customers with reliable solutions they can trust for years to come. This warranty is a testament to our commitment to customer satisfaction and our belief in the long-term value of our equipment.

We are family owned and operated and the originators of retail blister packaging since 1949. There are other options out there, but when it comes to knowledge, personalized experiences, and trust…we have your back. We believe customer service is key to success in any business and we value long lasting relationships with our customers

and their products.